With the goal of becoming a corporate citizen with environmental responsibility, Fukuda Mining Co., Ltd. has advanced technology and rich experience, which can provide efficient environmental remediation solutions, covering tailings pollution control and contaminated soil. The company cooperates closely with universities and research institutions to continuously improve technological innovation and create an innovation system of industry-university-research linkage.

(1)Tailings repair management

In the process of mine operation, high standards are strictly followed and the whole life cycle is carried out. Ecological restoration,customization and implementation of optimal management strategies in line with the actual situation of the mine to ensure land and water resources.

>Standard discharge of waste

Use advanced purification and disposal processes to ensure that solid, liquid and gaseous waste is discharged to standard standards, while taking measures to protect water resources and reduce the risk of environmental pollution from the source.Through rainwater collection and treatment, water purification standards are met, and the recycling of water resources is realized. At the same time, the discharge of heavy metals and other pollutants is significantly reduced, the risk of pollution is reduced, and the ecological environment is protected.

>Recycling of tailings

Strictly implement tailings management standards, ontinuously optimize the technical means and management capabilities of tailings treatment and resource recovery, promote the comprehensive utilization of tailings, and significantly reduce waste emissions.

>Environmental restoration of mines

Carry out environmental restoration projects, reshape the landscape, improve the soil, replant vegetation, and combine actual conditions to create a comfortable environment for mines and related persons through measures such as the restoration of closed mines into mine parks and tourist attractions.

(2)Reuse of urban mineral resources

’Urban mineral ‘ is a valuable renewable resource. Fukuda Mining Co., Ltd. has been deeply engaged in this field for nearly 20 years. From recycling channels to processing and utilization processes, it has professional capabilities.There are a wide range of resources, covering waste metals, wires and cables, waste home appliances, electronic products, and scrap automobiles. Through high-value recycling, the shortage of resources can be effectively alleviated, environmental pollution can be reduced, and contributions to the circular economy can be made.

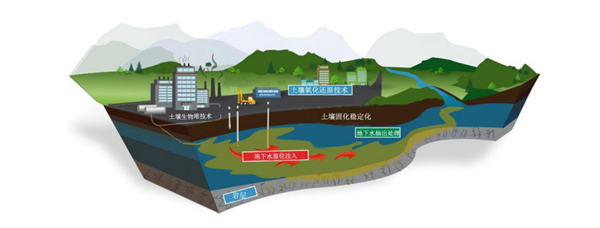

(3)Restoration of contaminated soil and groundwater

Soil restoration issues have received high attention from the government and society, and the company’s shareholders have accumulated deep industry background and rich experience in the field of environmental governance.Relying on the advantages of shareholders, the company can provide customers with site surveys, Risk assessment, customization of repair process plans, project implementation and other “one-stop” environmental governance services.Through biological ventilation, biodegradable, phytoremediation, chemical oxidation, electrodynamic separation, soil leaching, soil gas extraction, immobilization/stabilization, heat treatment and other repair methods, the goal is to restore the environmental quality to the ideal state.

(4)Engineering of biometallurgical technology

Urban mines are a treasure trove of resources rich in a variety of metals, including electronic waste and waste alloy materials. The company adopts biometallurgical technology and uses specific microorganisms such as Thiobacterium acidophilus and Thiobacterium ferrous oxide, Selectively dissolve metal minerals under mild conditions to achieve efficient metal leaching.Combining ion exchange, solvent extraction, electrodeposition and other technologies, the metals in the leaching solution can be recycled, the refined and green utilization of resources can be realized, and the energy consumption and pollution of traditional extraction processes can be reduced.

Tailings contain unrecoverable low-grade ores and associated metals, which are inefficient in traditional treatment and pollute the environment.The company adopts biometallurgical technology to use thermophilic and acidophilic microorganisms to metabolize and oxidize sulfides in tailings and releaseValuable metal.By optimizing the microbial growth environment, improving the leaching efficiency,and using membrane separation and adsorption technology to deeply separate and purify metals, improving the recovery rate, passivating the activity of heavy metals, reducing the risk of pollution, realizing the harm reduction and resource utilization of tailings, and supporting the sustainable development of mining.